BUILDING

Welcome to the real world.

Explore our gallery.

Welcome to the real world.

Explore our gallery.

Skrinex Polska was founded on the basis of many years of experience in construction, manufacturing, and engineering design, as well as the professional skills and knowledge developed in Ukraine. Our engineers, builders, installers, welders, and other specialists have successfully completed a significant number of complex construction and installation projects, including the production of steel structures and small concrete products such as paving slabs, road curbs, sidewalk curbs, and building blocks.

Between 2019 and 2022, our company's specialists carried out the following works commissioned by assets of Metinvest Holding LLC:

Currently, the core of the holding's workforce consists of engineers and qualified workers who have completed construction and installation projects across Ukraine — both for social infrastructure and for major metallurgical enterprises of the Metinvest Group.

Since 2023, our company has also been performing work at the sites of one of the world’s leading steel producers - ArcelorMittal, in its European divisions:

We carry out a range of projects, from installing cladding on load-bearing structures with profiled sheeting to assembling steelmaking equipment. For more details about our current operations, please visit the Current Experience section.

Installation of the scraper conveyor

Skidding of the reversible roughing stand for the LPCT 1700

Alignment and installation of the columns and beams for the water management system of the CCM No. 4 complex at Illich Iron & Steel Works

Installation of the supporting structure for the dust collection bunker

Installation of the gas duct, beam, and saddle in the design position

Installation of a producti on line for reinforced concrete products at our own manufacturing facility

INSTALLATION OF HEAVY EQUIPMENT (laser scanner for steel ladles 350 tones)

Installation of the roughing stand motor for the LPCT

Installation of the rolls for the curved frame (banana) of casting strand No. 4 for the continuous casting machine (CCM)

Installation of the end fitting for the main gas duct

Installation of the bag filter ducts

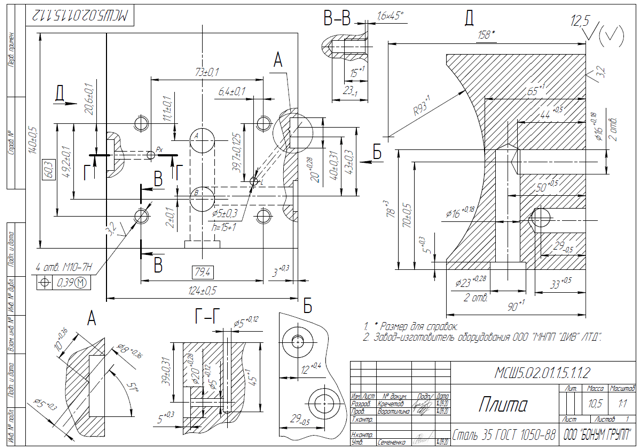

REVERSE-ENGINEERING AND REFURBISHING OF INDUSTRIAL EQUIPMENT (DE-SLUGGING MACHINE)

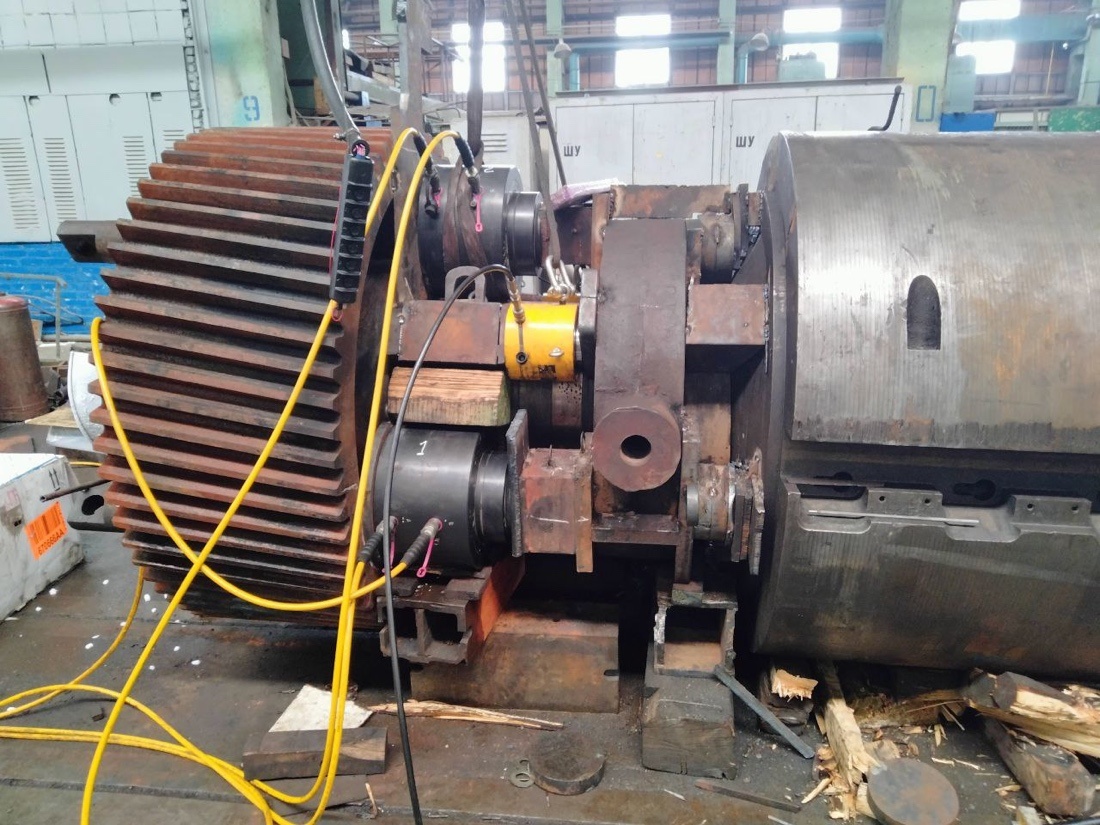

DISASSEMBLY, ASSEMBLY AND REPAIR OF HEAVY GEAR UNITS WITH HEATING, COOLING WITH DRY CO2 AND PRESSURE UP TO 1800 TONES

REPAIR OF INDUSTRIAL CARDAN SHAFTS

Dismantling of the press, delivery to the contractor's production site.

Disassembly of the press, preparation of a detailed and general defect list, inspection of all parts.

Restoration of the geometric accuracy of the press's guiding surfaces.

Inspection of the traverse movement mechanism with replacement of worn units and bearings.

The following works have been carried out from 2023 to the present.